Elkhart Plastics

-

img:corner-made-in-america-flag-overlay-80p.png

31 Gallon RV Holding Tank 34" x 19 1/2" x 13" Elkhart Plastics EPI 4848

Elkhart Plastics

$289.95SKU: RP-4848H$289.95 -

img:corner-made-in-america-flag-overlay-80p.png

32 Gallon RV Holding Tank 40" x 20" x 12" Elkhart Plastics EPI 3185

Elkhart Plastics

$304.95SKU: RP-3185W$304.95 -

img:corner-made-in-america-flag-overlay-80p.png

38 Gallon Water Tank 59" x 36" x 5" Elkhart Plastics EPI 4367

Elkhart Plastics

$379.95SKU: RP-4367W$379.95 -

img:corner-made-in-america-flag-overlay-80p.png

42 Gallon RV Holding Tank 66" x 21" x 9" Elkhart Plastics EPI 366H

Elkhart Plastics

$374.95SKU: RP-0366$374.95 -

img:corner-made-in-america-flag-overlay-80p.png

50 Gallon RV Holding Tank 53" x 27" x 10 1/2" Elkhart Plastics EPI 4418

Elkhart Plastics

$309.95SKU: RP-4418A$309.95 -

Out of stockimg:corner-made-in-america-flag-overlay-80p.png

50 Gallon RV Holding Tank 84" x 25" x 8" Elkhart Plastics EPI 0140H

Elkhart Plastics

$449.95SKU: RP-0140$449.95 -

Out of stockimg:corner-made-in-america-flag-overlay-80p.png

$294.95

$294.95 -

img:corner-made-in-america-flag-overlay-80p.png

62 Gallon RV Holding Tank 61 1/2" x 22" x 15" Elkhart Plastics EPI 4257

Elkhart Plastics

$489.95SKU: RP-4257H$489.95 -

Out of stockimg:corner-made-in-america-flag-overlay-80p.png

100 Gallon RV Water Tank 59" x 27" x 18 1/2" Elkhart Plastics EPI 0207W

Elkhart Plastics

$584.95SKU: RP-0207$584.95 -

Out of stockimg:corner-made-in-america-flag-overlay-80p.png

21 Gallon RV Holding Tank 78" x 25" x 4" Elkhart Plastics EPI 4585

Elkhart Plastics

$309.95SKU: RP-4585H$309.95 -

img:corner-made-in-america-flag-overlay-80p.png

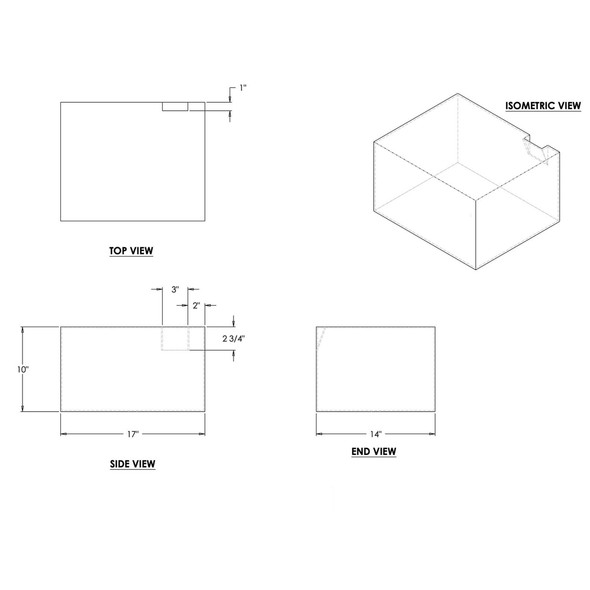

9.5 Gallon Fresh Water RV Tank 17" x 14" x 10" Elkhart Plastics

Elkhart Plastics

$104.95SKU: RP-1569A$104.95 -

img:corner-made-in-america-flag-overlay-80p.png

9 Gallon Fresh Water RV Tank 17" x 14" x 9 5/8" Elkhart Plastics

Elkhart Plastics

$104.95SKU: RP-0120$104.95 -

img:corner-made-in-america-flag-overlay-80p.png

$104.95

$104.95 -

img:corner-made-in-america-flag-overlay-80p.png

$114.95

$114.95 -

img:corner-made-in-america-flag-overlay-80p.png

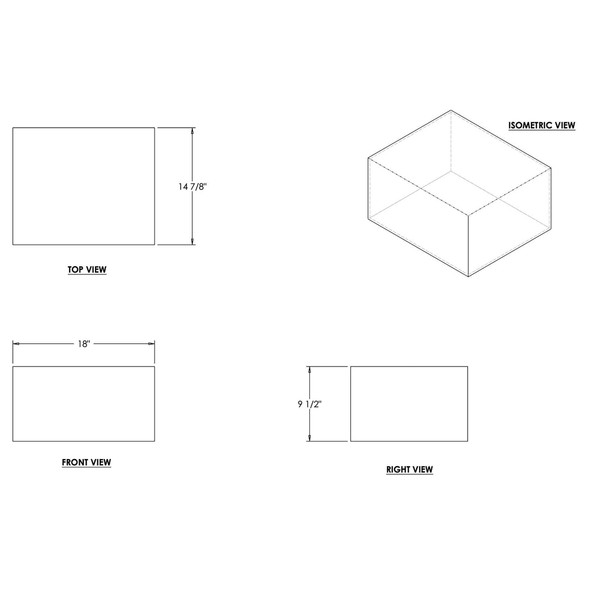

11 Gallon RV Water Tank 18" x 14 7/8" x 9 1/2" Elkhart Plastics EPI 0308W

Elkhart Plastics

$134.95SKU: RP-0308$134.95 -

img:corner-made-in-america-flag-overlay-80p.png

13 Gallon RV Water Tank 26 x 12 x 10 1/2 Elkhart Plastics EPI 4444

Elkhart Plastics

$249.95SKU: RP-4444$249.95 -

img:corner-made-in-america-flag-overlay-80p.png

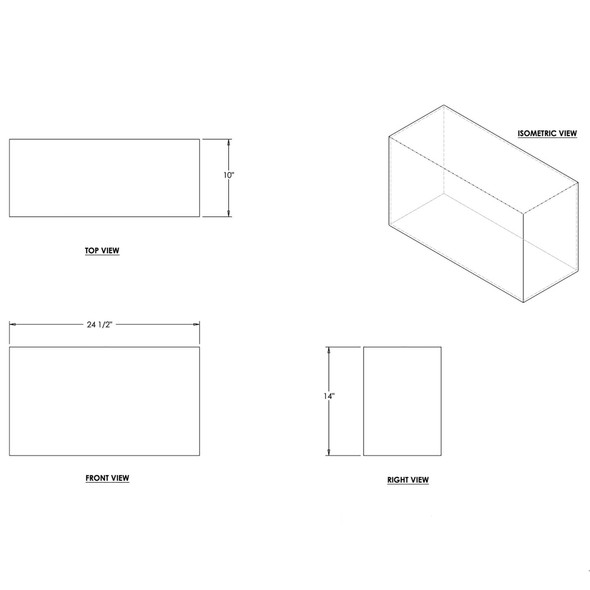

13.5 Gallon RV Water Tank 24 1/2 x 14 x 10 Elkhart Plastics EPI 272W

Elkhart Plastics

$164.95SKU: RP-272W$164.95 -

img:corner-made-in-america-flag-overlay-80p.png

$174.95

$174.95 -

img:corner-made-in-america-flag-overlay-80p.png

15 Gallon Fresh Water RV Tank 24" x 10" x 14" Elkhart Plastics

Elkhart Plastics

$124.95SKU: RP-1563A$124.95 -

img:corner-made-in-america-flag-overlay-80p.png

16 Gallon Fresh Water RV Tank 23 3/8" x 15 1/2" x 10 3/8" Elkhart Plastics

Elkhart Plastics

$139.95SKU: RP-131$139.95